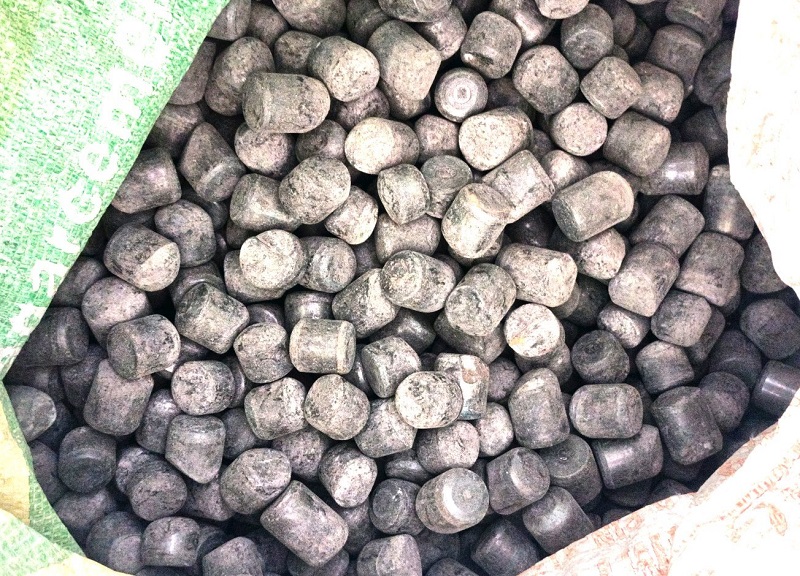

Tungsten carbide buttons are critical wear-resistant components widely used in DTH drill bits, tricone bits, mining tools, construction equipment, and industrial cutting applications. Known for their exceptional hardness, strength, and resistance to abrasion, tungsten carbide buttons are designed to perform under extreme pressure and high-temperature conditions.

Manufactured using a combination of tungsten carbide powder and a metallic binder, usually cobalt, these buttons provide outstanding durability and long service life. Their ability to maintain cutting efficiency in harsh environments makes them indispensable in mining and drilling industries.

In drilling operations, tungsten carbide buttons are strategically placed on the face and gauge of drill bits to crush and penetrate hard rock formations. These buttons absorb high-impact forces and resist rapid wear, enabling consistent drilling performance and reduced tool replacement frequency.

Due to their premium material composition and manufacturing complexity, tungsten carbide buttons carry high intrinsic value. Even after extended usage, when drilling tools become inefficient or damaged, the carbide buttons remain a valuable recyclable material.

Tungsten carbide buttons scrap includes used, worn, chipped, broken, or loose carbide buttons recovered from DTH drill bits, tricone bits, mining tools, and other industrial equipment. It may also include mixed-grade carbide scrap generated during tool manufacturing, reconditioning, or dismantling processes.

Despite wear or surface damage, tungsten carbide buttons retain significant tungsten content, making them one of the most valuable forms of industrial scrap. Proper recycling ensures maximum value recovery and responsible resource utilization.

Tungsten is a rare and strategically important metal with strong global demand. As a result, tungsten carbide buttons scrap commands high prices in the recycling market. The value of this scrap depends on factors such as tungsten content, cobalt percentage, cleanliness, size, and overall condition.

At Meonex Enterprises, we specialize in accurate grading and valuation of tungsten carbide buttons scrap. Our technical expertise ensures fair market pricing based on actual material quality, without hidden deductions.

Recycling tungsten carbide buttons requires specialized knowledge and careful handling. At Meonex Enterprises, our process begins with detailed inspection and segregation of carbide buttons by grade and condition. Contaminants and non-carbide materials are identified to ensure precise valuation.

The scrap is then weighed using calibrated systems and priced according to current market rates. Our transparent process ensures clients clearly understand how the scrap value is calculated, building long-term trust and reliability.

Scrapping tungsten carbide buttons with Meonex Enterprises is simple and efficient. Clients can collect loose buttons separately or provide used drill bits containing carbide buttons. We assist with segregation and logistics, especially for bulk quantities.

Once received, the scrap undergoes professional assessment, followed by a clear price quote. Upon confirmation, payments are processed promptly. Our streamlined approach ensures a hassle-free experience for all clients.

Fill out our contact form or call us now at (+91) 98295 52250, 97844 46716. Our team will assist you within 24 hours.

Recycling tungsten carbide buttons plays a crucial role in environmental sustainability. Extracting tungsten from ore is energy-intensive and environmentally demanding. Recycling significantly reduces energy consumption, greenhouse gas emissions, and mining-related environmental damage.

By choosing Meonex Enterprises for tungsten carbide buttons scrap recycling, clients actively support sustainable resource management and circular economy practices.

Meonex Enterprises is trusted by mining and drilling industries across Rajasthan for our expertise, transparency, and ethical business practices. Our clients choose us because we offer:

Rajasthan’s strong mining and drilling activities generate a steady supply of tungsten carbide buttons scrap. Meonex Enterprises has built a strong regional presence, serving mining companies, drilling contractors, quarry operators, and industrial manufacturers across the state. Our understanding of local industry requirements allows us to deliver efficient, dependable, and value-driven scrap solutions.

Tungsten carbide buttons are essential high-performance components in mining and drilling operations, and their value extends far beyond their operational life. Tungsten carbide buttons scrap represents a high-value recycling opportunity when handled by an experienced and reliable scrap company.

Meonex Enterprises stands as a trusted partner for tungsten carbide buttons and tungsten carbide buttons scrap recycling in Rajasthan, India, ensuring maximum value recovery, transparent pricing, and environmentally responsible recycling.

Copyrights © 2025 All Rights Reserved by Meonex Enterprises Pvt. Ltd.